Nanoslic Anti-Graffiti Coatings

The Problem

Graffiti-based vandalism is on the rise, costing an estimated $112 billion in annual cleanup expenses in the US alone. Although urban areas face the most issues, graffiti is found in all areas of the country.

Anti-graffiti coatings

There are two main categories of anti-graffiti coatings. While NanoSlic focuses on one type, we’ll discuss both to give you an idea of how our permanent solutions differ from so-called “sacrificial” coatings.

How sacrificial anti-graffiti coatings work:

Sacrificial anti-graffiti coatings form a clear coat barrier over the wall or surface being protected. If the surface is vandalized, the coating can be removed (or “sacrificed”) using a high-pressure washer. The graffiti goes away with the coating. The coating must then be reapplied.

Materials used to make sacrificial coatings are usually inexpensive, optically clear polymers (such as acrylates, biopolymers, and waxes). These polymers form weak bonds with the substrate to allow for easy removal. They also often help protect against corrosion and certain types of environmental damage.

The drawback?

Sacrificial coatings need to be reapplied as often as they’re removed. (Hence “sacrificial:” you’re sacrificing the entire layer in order to remove the graffiti with it.)

Advantages of Permanent Anti-Graffiti Coatings

Permanent anti-graffiti coatings are often more expensive than sacrificial coatings, but if used correctly, they only have to be applied once. In the long run, they’re often well worth it in terms of lower maintenance, upkeep, and re-application.

Permanent anti-graffiti coatings work by creating a protective surface that spray paint cannot bond to. After the surface has been vandalized, solvents or manufacturer-supplied cleaners are used to remove the graffiti. Clean-up is often just as easy as regular maintenance.

The underlying surface and the protective coating should remain undamaged. Some of the types of permanent coatings include those based on polyurethanes, nano-particles, fluorinated hydrocarbons, or siloxanes.

NanoSlic Permanent Anti-Graffiti Coating

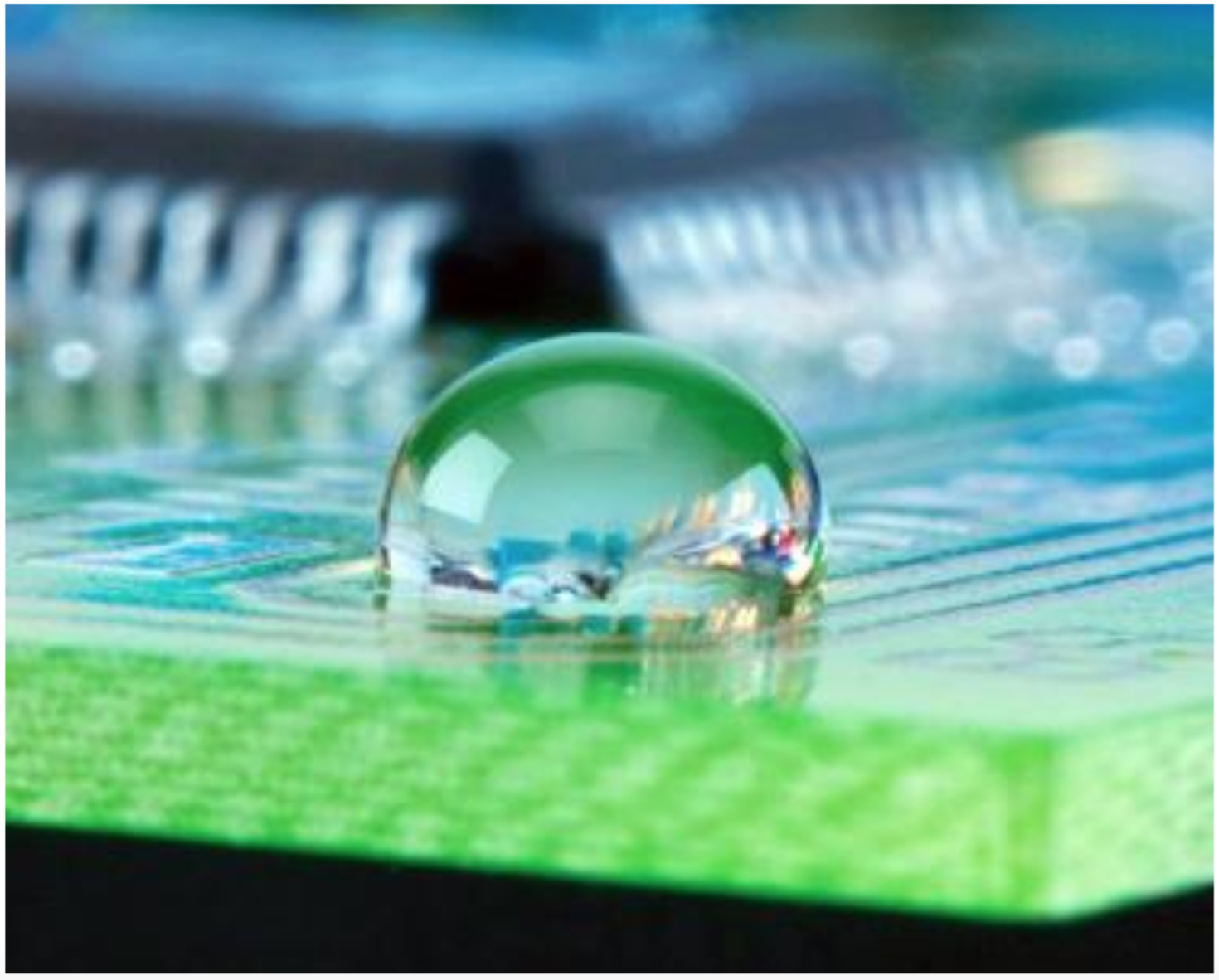

NanoSlic NS 240 is in the category of permanent anti-graffiti coatings. It uses a primary binder polymer that is ceramic, and largely composed of silica. As the coating cures, highly non-polar molecules align themselves in such a way to form the coating’s surface.

Watch the video above to see how NanoSlic resists spray paint, permanent marker, and more.

Unlike other anti-graffiti coatings, the surface is both hydrophobic and oleophobic, similar to polytetrafluoroethylene (Teflon). It’s completely resistant to all types of paints and inks. Any paint residue that does remain is easily washed away.

Below this layer, the bulk of the coating polymerizes into an inert silica-based structure. At the substrate surface, the polymer chemically bonds to hydroxyl groups on the substrate.

The advantage of this approach is that a high degree of adhesion and abrasion resistance is achieved to almost any surface. NanoSlic also acts as an ultra-durable topcoat protecting underlying paint from physical damage, UV degradation and other forms of degradation.

So, what is the real-world value?

Stop graffiti before it happens

When vandals attempt to spray paint or use permanent markers on your NanoSlic-protected property, they’ll likely find that it just… won’t stick. The graffiti is completely prevented. NanoSlic provides protection and a deterrent.

Apply once

NanoSlic is an ultra-protective topcoat that offers a graffiti-proof surface. The coating will hold up under adverse conditions, including sunlight, humidity, chemicals, and abrasion. And because it’s available in clear gloss and matte versions, it will protect the underlying surface aesthetics… or even enhance them.

NanoSlic Technology

NanoSlic nanocoatings combine hydrophobic and oleophobic nanotechnology to protect surfaces from all kinds of damage. They not only resist water- and oil-based substances, but also provide protection against scratches, chemicals, sun fading, and more.

NanoSlic maintains its properties over a large temperature range It’s engineered to withstand harsh conditions and protects the surface from oil, water, chemicals and more. 9H pencil hardness guards against scratches and another abrasion.

Unlike other ceramic coatings on the market, NanoSlic does not require a complicated application process.

NanoSlic Applications

Our ceramic coatings can be used to protect a wide range of products and surfaces from graffiti, including:

- Transportation: Railroads, subways, buses

- Public Spaces: Bus stops, train stations and terminals

- Industrial and marine surfaces

- Almost any metal, ceramic, plastic, or polymer surface

Order a sample of NanoSlic anti-graffiti coating and test it out for yourself.