Protective Ceramic Coatings for Industrial Surfaces

Nanoslic is a new type of protective coating.

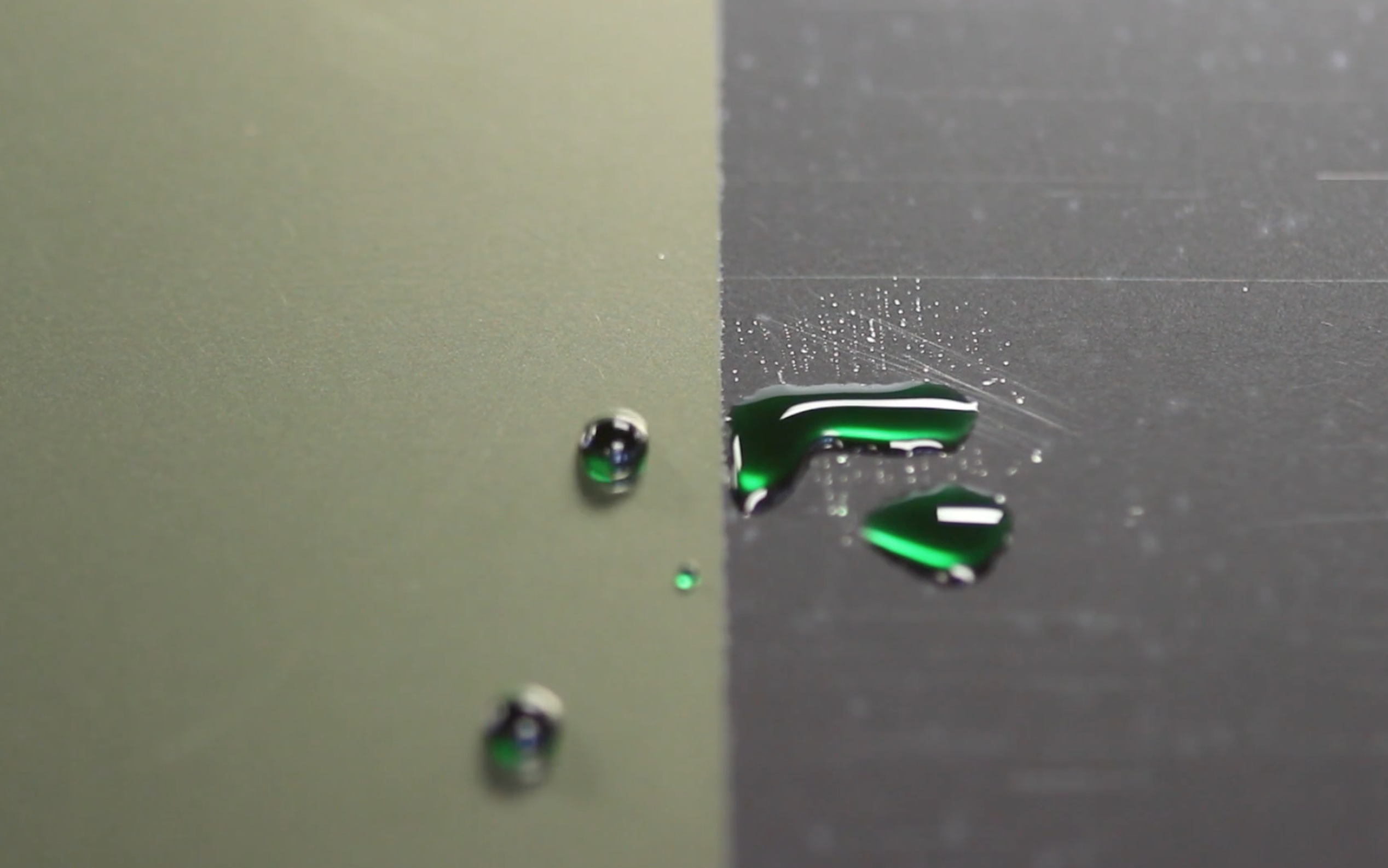

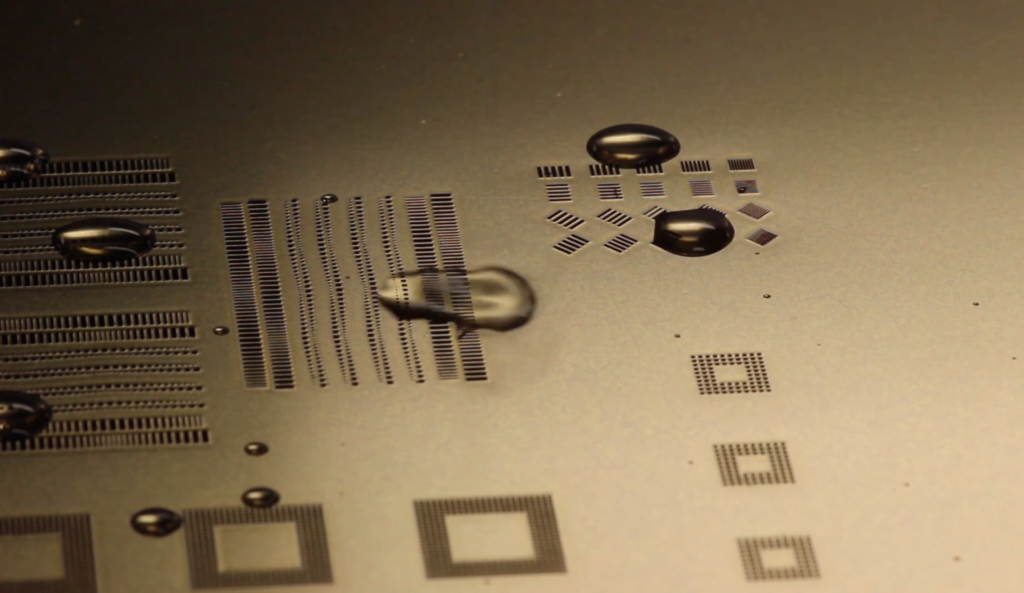

Hydrophobic

Nanoslic’s hydrophobic properties prevent water-based substances from sticking to the surface. This makes the surface easy-to-clean, slippery and prevents corrosion.

Oleophobic

Not only does Nanoslic repel water, but it is also oleophobic. It repels oil-based substances. This includes oils, grease, tar, fingerprints.

Permanent

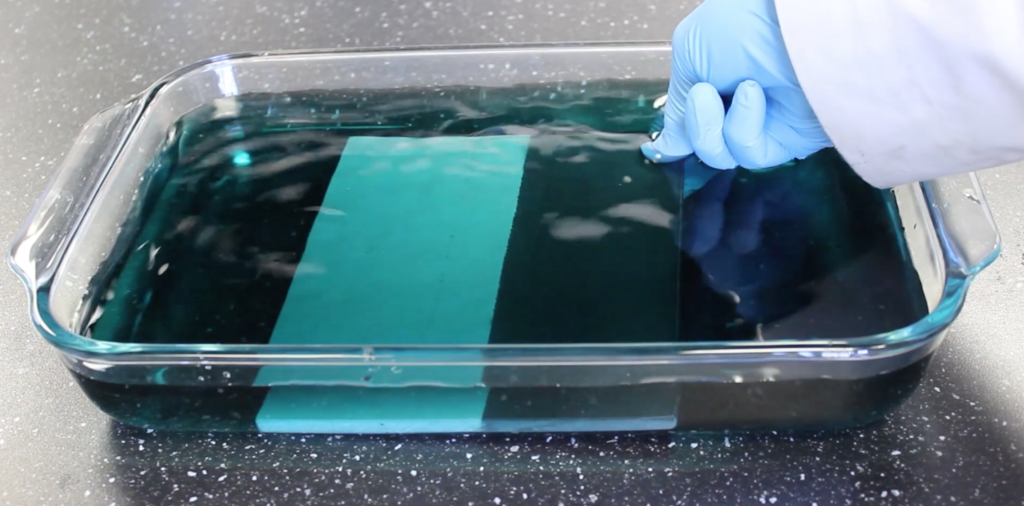

Generally, hydrophobic and superhydrophobic coatings offer little abrasion resistance. NanoSlic is a ceramic-based coating. It is inert and most formulations have a 9H hardness. In most applications it is designed to be permanent.

Corrosion Resistance

Due to its hydrophobic and oleophobic properties, Nanoslic helps prevent corrosionby repelling water and chemicals that lead to corrosion.

Industries Using Nanoslic

NanoSlic protective coatings can be used for a variety of industrial applications. The durable, hydrophobic coating improves hard surfaces making them resistant to deterioration. NanoSlic also seals out water which can lead to corrosion, thus extending the overall life of industry surfaces.