SMT Stencil Coatings

NanoSlic Smart Coatings offers the world’s most advanced SMT Stencil Coatings. Our coatings improve print transfer efficiency, minimize bridging and other defects, improve cleaning efficiency and much more.

Ready to start your SMT stencil project? Let’s Talk.

Premium SMT Stencil Coating

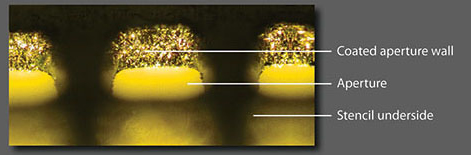

The NanoSlic coated stencil is the next generation of stencil coating technology developed to address increasing demands facing the electronic assembly industry. This stencil is based on a proprietary application process that coats both the underside of the stencil and aperture walls.

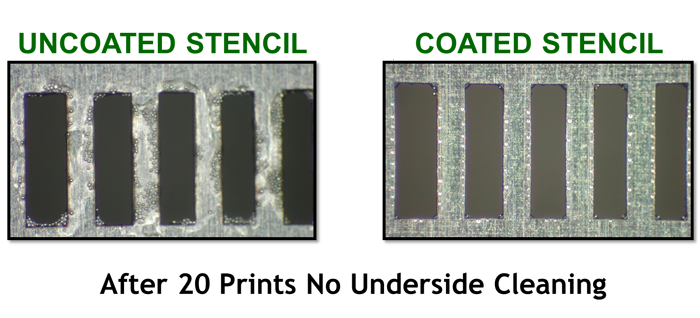

This durable coating is both highly hydrophobic and oleophobic, which repels solder paste. NanoSlic is thermally cured and is a permanent coating. This technology significantly improves solder paste transfer efficiencie for small apertures resulting in higher yields and less rework.

It also minimizes bridging and reduces underside cleaning. This coating technology is compatible with current assembly equipment and processes.

Purchase NanoSlic Stencils from our Licensees

NanoSlic has a global network of licensees to support and manufacture coated stencils for the SMT industry. Licensees us only the NanoSlic Stencil Coating System developed by NanoSlic Smart Coatings. This system offers a more efficient and effective process for coating stencils, incorporating a number of proprietary features specifically designed around NanoSlic’s unique chemistry.